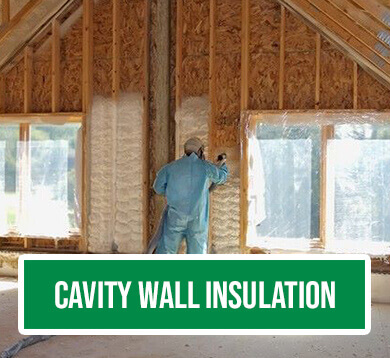

Cavity wall insulation – installation process for bonded bead insulation.

Cavity wall insulation – installation process for bonded bead insulation.

Cavity wall insulation – installation process for bonded bead insulation.

Cavity wall insulation – installation process for bonded bead insulation.

It’s the best system. We install all the different types of insulation material but this system really performs better.

Safest and last forever. Open cell insulation is fantastic due to it’s safety, it performs perfectly and lasts forever. The material is permeable (or breathable, as people say) just like the timbers and felts.

Install ventilation cards. We install spacer cards between the rafters in the roof which maintains ventilation which ensures moisture is taken away. This ventilation gap can be either inside or outside the breathable felt on the roof. The open cell insulation bonds and seals between all the different building fabrics stopping cold air and trapping heat perfectly. This is where a lot of the other systems fail they can’t stop the cold air or they break down over time. They don’t perform or last as well.

Open cell insulation comprises ultra low density permeable water blown through a spray foam insulation system for use on building fabrics like roofs walls floors.

The system is certified both European and Irish Open cell insulation can be applied both vertically and horizontally due to its high reactivity. It is also perfect for overhead spraying.

The timbers density is anywhere from 500 – 150 kg/m3. Open cell insulation density is 8 – 20 kg/m3 so permeability is guaranteed

Open cell insulation can only be processed by suitable 2 component spray foam insulation machines that were especially designed for this purpose. Have a look at ours.

The beads are moisture proof and allow or guide and moisture downwards, a process known as capillary action Beads have great lamda values and can then help you achieve the best U values. Architects are specifying cavities from 100mm to 200mm to be pumped with beads.

In order to make the perfect foam mixing heating pressure raw material machinery conditions must all be right.

These Graco machines are equipped with constant heating elements which heat the raw materials and hoses to the guns. The temperatures required during spraying is 40 – 60 degrees and the mixing ratio is 100: 100 parts by volume.

To get the perfect open cell insulation material the mixing must be perfect, the pressure of both the A and B components should be at least 40 Bar at the gun. The pressure of the Graco reactor is set at greater than 65 during spraying. Hoses lengths and diameters and mixing chambers are taken into account.

Good mixing of both components in the ratio is essential to obtain the optimal properties. Open cell insulation can only be applied to clean dry warm surfaces never applied to greasy dusty wet cold. Surfaces that are not suitable for open cell insulation e.g. Metal concrete dusty high moisture content should be treated with an adhesion promoter or coating. When surfaces are not suitable bad adhesion is probable. Adhesion is always tested prior to the full application of the open cell insulation system.