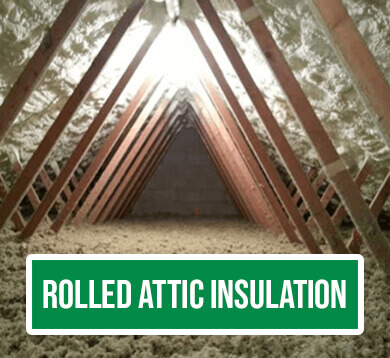

Rolled attic insulation is the most common method used for attic insulation, primarily because it is the easiest method to use. There are then different types of rolls of wool fibres for specific insulation tasks, all having different densities, thermal conductivities and sizes. The density determines how it performs and how long it lasts, also indicating the quantity of material in the rolled attic insulation wool fibre. The thermal conductivity is the measurement used when calculating how well heat moves through the rolled attic insulation, or any other building material. We can buy the rolls in 4” (100mm) 6” ( 150mm) and 8” (200mm). It is important to match up the sizes of the timbers with our rolled attic insulation materials and then match them perfectly as this ensures any air and cold moving between the layers is stopped. It’s very hard to do this with layers of wool and timbers in between. There are mainly four different types of wool fibres being used at present for rolled attic insulation – they are glass wool, earth wool, rock wool and sheeps wool. When we use rolls of wool for rolled attic insulation of buildings we must ensure that we are able to stop air movement along the timbers and under the layers of wool in order to insulate successfully. If we do not ensure that this air movement is stopped then we will not experience comfort and we will continue to spend more on heating bills. The wool layer should be installed 12” (300mm) deep in order to achieve the building regulations Uvalue. The Uvalue is calculated by dividing the thermal conductivity by the thickness of the material. Contact us now to arrange a CONSULTATION so we can provide you with the best system, best advice and best price.

Read more about Insulation Regulations.

Quickly evaluate your potential energy efficiency.

Rolled attic insulation is the most common method used for attic insulation, primarily because it is the easiest method to use. There are then different types of rolls of wool fibres for specific insulation tasks, all having different densities, thermal conductivities and sizes. The density determines how it performs and how long it lasts, also indicating the quantity of material in the rolled attic insulation wool fibre. The thermal conductivity is the measurement used when calculating how well heat moves through the rolled attic insulation, or any other building material. We can buy the rolls in 4” (100mm) 6” ( 150mm) and 8” (200mm). It is important to match up the sizes of the timbers with our rolled attic insulation materials and then match them perfectly as this ensures any air and cold moving between the layers is stopped. It’s very hard to do this with layers of wool and timbers in between. There are mainly four different types of wool fibres being used at present for rolled attic insulation – they are glass wool, earth wool, rock wool and sheeps wool. When we use rolls of wool for rolled attic insulation of buildings we must ensure that we are able to stop air movement along the timbers and under the layers of wool in order to insulate successfully. If we do not ensure that this air movement is stopped then we will not experience comfort and we will continue to spend more on heating bills. The wool layer should be installed 12” (300mm) deep in order to achieve the building regulations Uvalue. The Uvalue is calculated by dividing the thermal conductivity by the thickness of the material. Contact us now to arrange a CONSULTATION so we can provide you with the best system, best advice and best price.

When we are deciding on a method and material for a rolled attic insulation we ensure you get the best results and longest lasting material. We stop heat escaping and air getting in, providing a comprehensive rolled attic insulation service. Get in touch now at (1890) 90 90 22 or fill in our contact form or find our office on a map at the link below to arrange your CONSULTATION and/or QUOTE.

The water tank and pipework should always be insulated neatly with 22mm pipe insulation. There should be no gaps at all in the rolled attic insulation, as frost can cause the pipework to expand and crack. The corners and all T-junctions should be dressed neatly and tightly wrapped with the correct tapes.

If you require to use your attic for storage then we simply counter batten using 6 “ timbers then install the plywood sheets or use an insulated ply board, ensuring that we have two insulation methods where there is storage. If the tanks are a few meters distance from the entrance hatch to the attic this detail should be extended to the water tanks and is then called a walkway. This ensures that plumbers or yourself can access the water tanks, without disturbing the rolled attic insulation. The eves ventilation should always be protected to stop the rolled attic insulation from sweating. Along the eves care must be taken not to obstruct the air flow from the facia and soffit ventilation, while a 50mm air gap must be maintained. This detail is checked during the home survey and if there is no ventilation present it is wise to install ventilation to the building standards. Call Dave on (087) 975 0914, (1890) 90 90 22 or fill in our contact form to arrange a CONSULTATION.

Read about our glass wool manufacturers.

Read about our Earth Wool manufacturers